What is the role of reinforcement for screen tubes?

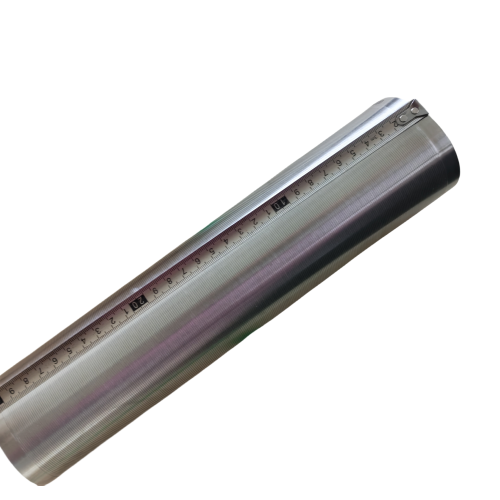

In the industrial screening field, wedge wire screens are a key filter element widely used in industries such as petroleum, chemical, water treatment, and mining. Their performance directly impacts screening efficiency, equipment lifespan, and operating costs. While seemingly minor, reinforcing ribs play a crucial role in the structural design of screens.

1. Enhance mechanical strength and resist deformation and fatigue.

During operation, wedge wire screens must withstand material impact, vibration loads, and cyclic stress. Weak structures can easily lead to localized deformation, fracture, or fatigue damage. Reinforcement ribs, through longitudinal or circumferential reinforcement, significantly enhance the compressive, bending, and torsional strength of the screens. They effectively disperse stress concentrations and prevent structural failure. Especially under high-pressure and high-frequency operating conditions, the presence of reinforcement ribs ensures long-term stable operation of the screens.

2. Optimize screening accuracy and stability.

Reinforcement ribs not only strengthen the screen's physical structure but also help maintain the stability of the mesh shape. Without support ribs, the wedge wire screen can deform under material impact, causing mesh size changes or clogging, impacting screening accuracy and efficiency. Through the rational placement of reinforcement ribs, the screen surface remains flat and aperture uniformity is ensured.

3. Extending service life and reducing maintenance costs.

Wedge wire screen damage often begins with localized stress concentration or fatigue cracks. Reinforcement ribs strengthen weak areas, slowing crack propagation and reducing the frequency of unplanned downtime. Furthermore, the reinforcement rib design can be combined with anti-corrosion coatings and wear-resistant materials to form a multi-layered protective layer, further extending the service life of the screen in harsh environments.

4. Adapting to diverse application scenarios.

Different industries have varying performance requirements for screens: oil screens must withstand high pressure, mining screens must resist wear, and food-grade screens must avoid structural dead zones. Reinforcement ribs can be customized to meet specific needs, such as adjusting rib thickness, layout density, or material, to precisely match screen performance to specific application requirements.

Though inconspicuous, reinforcement ribs are an essential component of wedge wire screen structural design. With their scientific mechanical support and long-term protective mechanism, they silently safeguard the integrity and functionality of the screen. Choosing a screen with a reasonable reinforcement design is not only a technical optimization, but also a far-reaching investment in production efficiency and cost control.

Any requirements, contact us now!

Nina

Email: nina@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 172 6957 1060