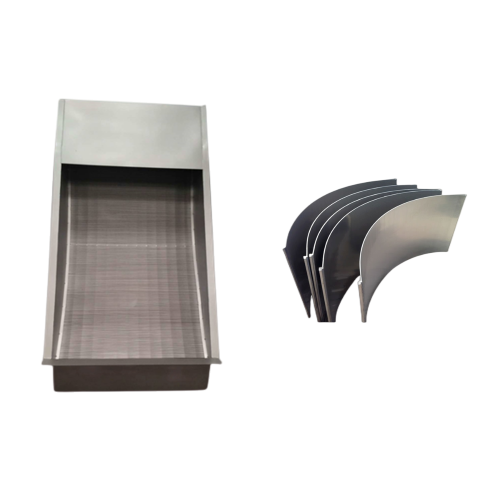

Why Choose Sieve Bend Screen?

In the water treatment industry, Sieve Bend Screen primarily serve as "pretreatment guardians" and "resource recovery experts." Their core value lies in the efficient and energy-saving separation of fine suspended solids from liquids, thereby protecting subsequent critical equipment and potentially recovering valuable materials.

Sieve bend screens are typically placed at the front end of the wastewater treatment process or before specific process steps. Their primary purposes are:

1. Protecting pumps and pipes: They remove easily entangled materials such as hair, fibers, and plastic fragments to prevent clogging, entanglement, and wear of pump impellers, and thus prevent pipe blockage.

2. Reducing the load on subsequent treatment units:

For biochemical treatment: They remove persistent solids, which occupy the biochemical tank volume, increase sludge production, and are difficult for microorganisms to decompose.

For membrane treatment: This is a particularly important application for sieve bend screens. Fine particles are the natural enemy of membrane systems and can quickly cause membrane fouling and clogging. Using hydraulic screens as pretreatment can significantly extend membrane life, reduce the frequency of chemical cleaning, and lower operating costs. For sedimentation tanks/flotation tanks: Pre-removing some suspended solids can improve sedimentation or flotation efficiency and reduce the amount of chemical added.

Advantages of sieve bend screens:

- Energy Saving and Consumption Reduction: Powered by water energy, it requires no external motor drive, resulting in extremely low operating costs.

- Continuous Self-Cleaning: Highly automated, it allows for the cleaning of the screen surface without interrupting operation, ensuring continuous and stable processing.

- Reduced Maintenance Costs: Simple structure, few moving parts, low failure rate, and minimal maintenance.

- Resource Recovery: It can effectively recover valuable materials such as fiber and feed from the water, generating significant economic benefits.

- Improved Working Environment: It quickly separates dirty and smelly solid debris from the water and transports them away in a sealed manner, reducing odor emission and manual labor.

Sieve bend screens are not core processing units in the water treatment industry, but they are crucial auxiliary and pre-treatment equipment. Through its efficient and energy-saving solid-liquid separation characteristics, it provides a solid guarantee for the stable, efficient and low-cost operation of the entire treatment system. It is an indispensable process in modern water treatment plants, especially industrial wastewater treatment plants.

Any requirements, contact us now!

Nina

Email: nina@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 172 6957 1060