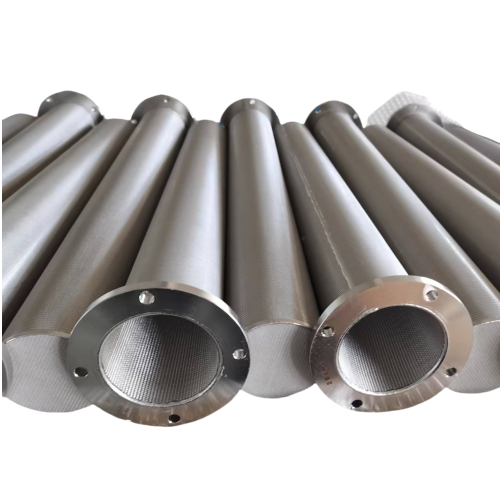

What's the Advantage of Screen Made of Perforated & Sintered Mesh?

Perforated mesh + sintered mesh composite screen is an innovative screen that combines the dual advantages of perforated mesh structure matrix and precision sintered metal wire filter layer, redefining the reliability of industrial filtration with excellent performance.

The combination of perforated mesh matrix and sintered filter layer has achieved a significant leap in performance.

- Ultra-high strength and durability: The rigid support of the perforated mesh greatly improves the compression and bending resistance of the overall structure, and extends the service life in high pressure and vibration environments.

- High flux and low pressure: The large opening rate of the perforated mesh guarantees the basic flow capacity, and the high porosity and uniform pore size of the sintered filter layer ensure high flux and low operating pressure drop in the filtration process, significantly reducing system energy consumption.

- Precise and stable filtration accuracy: The sintered layer provides highly reliable and lasting filtration accuracy, effectively intercepts impurity particles of the target particle size, and ensures the purity of the downstream medium and process stability.

- Excellent anti-clogging and easy cleaning: The deep filtration characteristics of the sintered filter layer combined with its surface smoothness significantly reduce the risk of clogging; its good cleanability greatly reduces maintenance frequency and downtime.

- Wide adaptability: By selecting different materials and adjusting the aperture parameters, it can adapt to extreme working conditions such as high temperature, high pressure, and corrosive media.

Typical application areas

Due to its reliable performance, this composite structure screen has become the preferred solution in the following key areas.

- Oil and gas: downhole sand control screen, production string filter section, water injection well filtration.

- Chemical and pharmaceutical: reactor inlet/outlet filtration, catalyst carrier and recovery, solvent fine filtration, high-purity medium transportation.

- Water treatment: seawater desalination pretreatment, industrial wastewater precision filtration, membrane system security filtration, circulating water system.

- Food and beverage: precision filtration and clarification of liquid foods such as syrup, edible oil, wine, and juice.

- Energy and environmental protection: coal-fired/gas-fired power plant water vapor system, biomass energy processing.

We are committed to providing a variety of materials, specifications and customized solutions to meet the stringent requirements of different industrial scenarios.

Any requirements, contact us now!

Nina

Email: nina@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 172 6957 1060