Why Choose JX Filtration's Sieve Bend Screen?

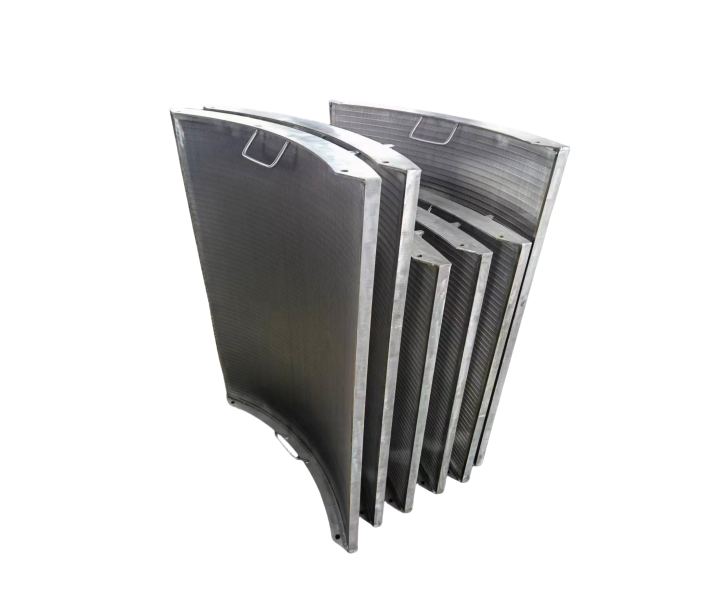

Sieve Bend Screen with their unique design and superior performance, are becoming the ideal choice for industrial screening. In industries such as mining, coal mining, wastewater treatment, and food processing, the efficiency and durability of screening equipment directly impact production efficiency and cost control. The advantages of sieve bend screens are briefly introduced below:

1. High-efficiency screening, anti-clogging design.

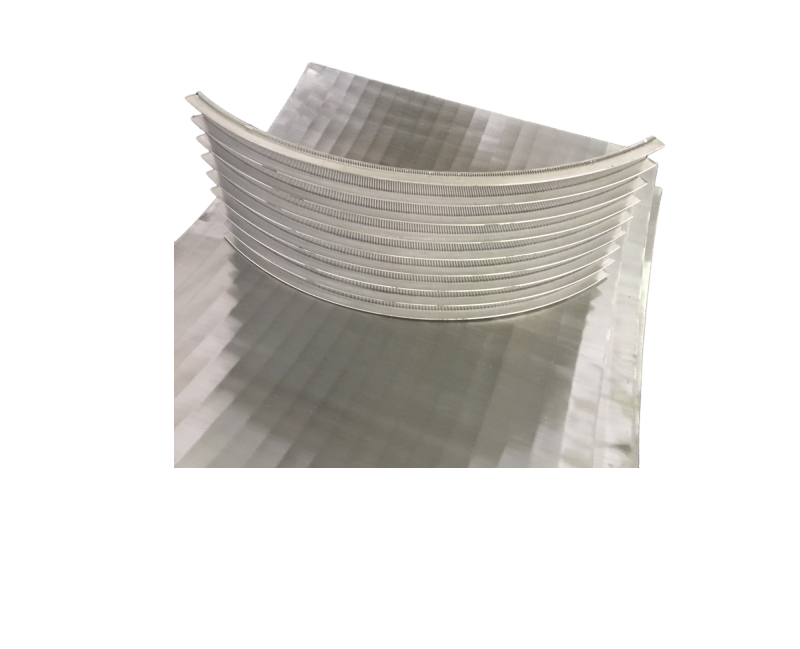

Sieve bend screens utilize a V-shaped wedge-shaped wire mesh structure, with the screen openings gradually narrowing from top to bottom, effectively preventing particle clogging and ensuring a continuous and efficient screening process. The arc design further increases the water flow area, improving the throughput of liquids or fine materials. It is especially suitable for screening high-moisture, high-viscosity materials.

2. High strength, wear-resistant, and durable.

The wedge-shaped arc screen plate is made of high-quality stainless steel, possessing extremely strong impact resistance and wear resistance, capable of withstanding high-load working environments for extended periods.

3. Self-cleaning, reduced maintenance.

The unique arc structure and wedge wire arrangement generate micro-vibration forces during the screening process, automatically cleaning the screen openings and improving production efficiency.

4. Widely applicable and customizable.

Suitable for industries such as mining, metallurgy, coal, wastewater treatment, food, and chemicals. We can customize screens of different sizes, curvatures, and materials to meet diverse screening needs.

Whether improving production efficiency or reducing operating costs, sieve bend screens provide reliable support for your industrial screening system.

Any requirements, contact us now!

Nina

Email: nina@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 172 6957 1060