Rotary Drum Screen for Paper Mill

The 15-20 micron pore filtration process is called microfiltration. Microfiltration is a method of mechanical filtration. It is suitable for filtration and separation of the tiny suspended substances (pulp fibers) existing in the liquid to the greatest extent, so as to achieve the purpose of separation of solid and liquid phases. The difference between microfiltration and other methods is that the filter medium has a particularly small gap. With the help of the centrifugal force of the screen rotation, it has a high flow rate and retains suspended solids under low hydraulic resistance.

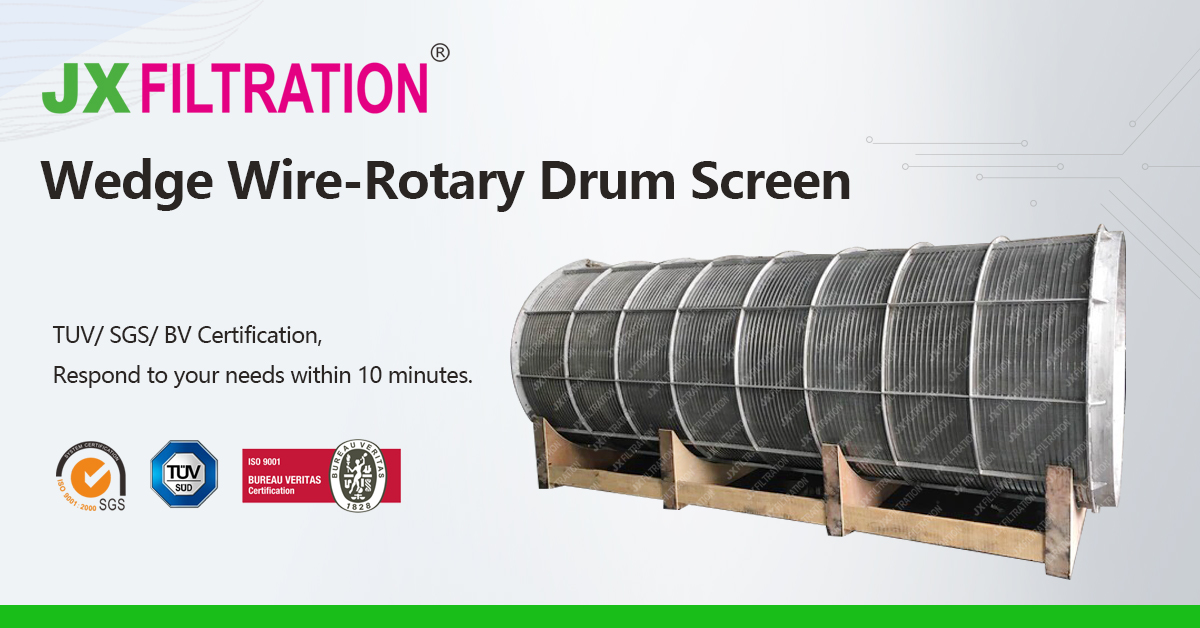

JX Filtration can manufacture largest Dia. 2000 x length 6500mm rotary drum screen for paper-making industry. The wedge wire type rotary drum screen is welded by winding the support bar around the strip. JX Filtration add suitable stiffeners as well. It has high welding strength, uniform gap, high precision, corrosion resistance, long service life, smooth inner surface of the filter cartridge and perfect roundness.

The rotary drum screen produced by our company are widely used in various large and medium-sized filtering equipment, such as automatic cleaning filter, scraper filter, automatic sewage filter, channel drum filter, rotary drum filter, solid-liquid separation equipment such as ion exchangers. The wedge wire type rotary drum screen has a filtration precision range of 20 microns-10mm. The main materials are 304, 316L, 2205, 2507 and can also be designed and produced according to customer requirements.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160